"How to Improve the Efficiency and Safety of the Scrap Metal Baler: A Comprehensive Guide for Beginners"

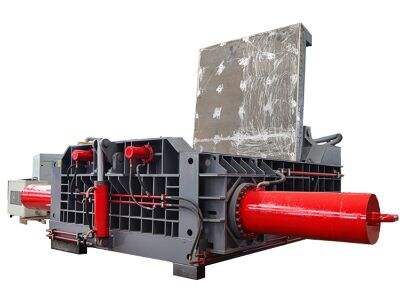

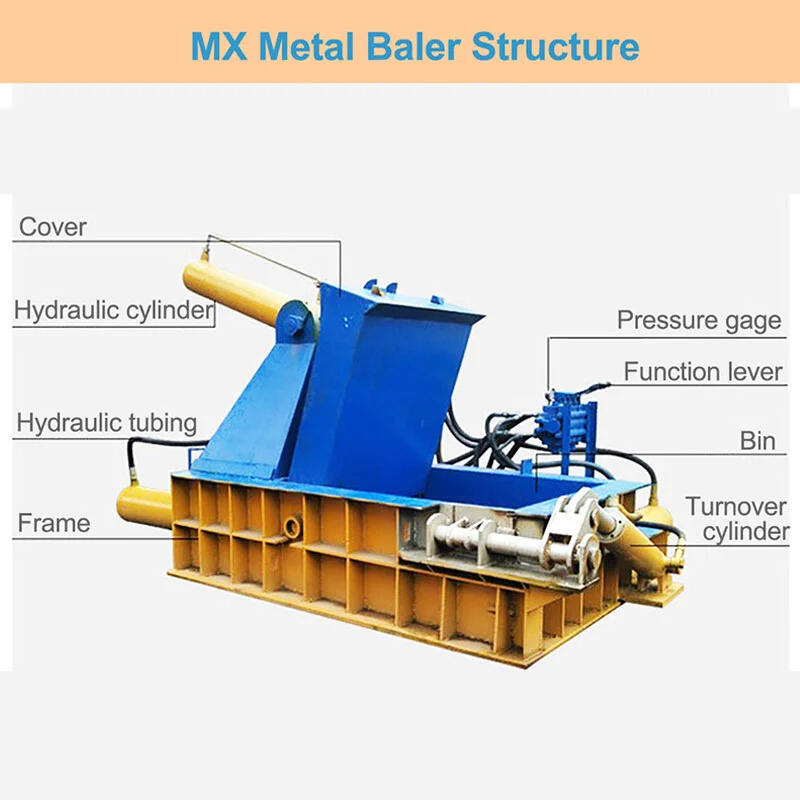

Scrap metal balers are machines that assistance to compact and recycle metal waste. The Mingxin show up in different sizes and types, and are utilized in lot of companies such as manufacturing, construction, and recycling. We will speak about the advantages of utilizing a scrap metal baler, the absolute most recent innovations the market, how to safely and effectively use the machine, where you might get quality service, and their applications in different sectors.

Advantages:

The scrap metal baler is a useful guitar can help reduce waste disposal costs, save yourself time and effort, and generate revenue from recycling. By compressing the metal waste into little packages, you will transport them effortlessly to recycling places. Furthermore, the metal can be sold by you at a revenue, while the compacted form melts away less area and includes a greater benefits. Additionally, utilizing a scrap metal baler can help lessen your carbon footprint by cutting your waste output and contributing to a circular economy.

Innovation:

The newest innovations in scrap metal balers have made them more effective, user-friendly, and safe. Modern balers include high level features for example automatic feed, computer-controlled operations, and safety products. Perhaps one of the most fun developments the use of hydraulic power, that allows the machine to exert greater pressure on the compactors and balers metal waste and produce tighter, denser bales. This leads to a higher yield and the reduced environmental influence.

Safety:

Safety is vital whenever using a scrap metal baler. It is important to master the maker's instructions and follow safety guidelines to avoid accidents and accidents. Many of the safety features of contemporary balers include emergency stop switches, interlocks, safety gates, and warning labeling. It is essential to put appropriate personal protective equipment such as gloves, safety glasses, and steel-toed footwear once operating the machine. It is additionally better to examine the apparatus frequently for use and tear, and to replace hurt or section being worn-out making use of it again.

Use:

Employing a scrap metal baler need some basic knowledge of machine. Begin by inspecting the product to ensure that it is clear of non-metallic items such as plastic, rubber, or wood. These materials can harm the garbage baler and even lead it to malfunction. Next, load the metal waste to your hopper, making certain so it is evenly distributed. Turn on the machine and allow it do their work. After the bale is complete, take it off through the chamber and shop it in an safer area it is ready to feel transported for recycling.

Service:

To take care of the effectiveness and safety associated with scrap metal baler, it is important to acquire quality service from the reputable provider. Locate a service company which specializes in scrap metal balers and has experiences in repairing and keeping often causes various brands. They need to be able to offer a comprehensive repair maintenance that features regular inspections, cleaning, lubrication, and substitution of worn-out section. The reliable service should offering your prompt assistance in case there is breakdowns or emergencies.

Application:

Scrap metal balers are used in many different sectors such as automotive, construction, manufacturing, and recycling. Within the automotive industry they've been put to compact and recycle metal cardboard baler machine parts such as vehicle systems, engines, and transmissions. In to the construction industry, they have been put to compress scrap metal balers such as metal beams, pipes, and cables. When you look at the manufacturing sector, they have been accustomed to recycle metal waste from manufacturing procedures. To the recycling industry, they are used to compress and transport metal waste to recycling business.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ