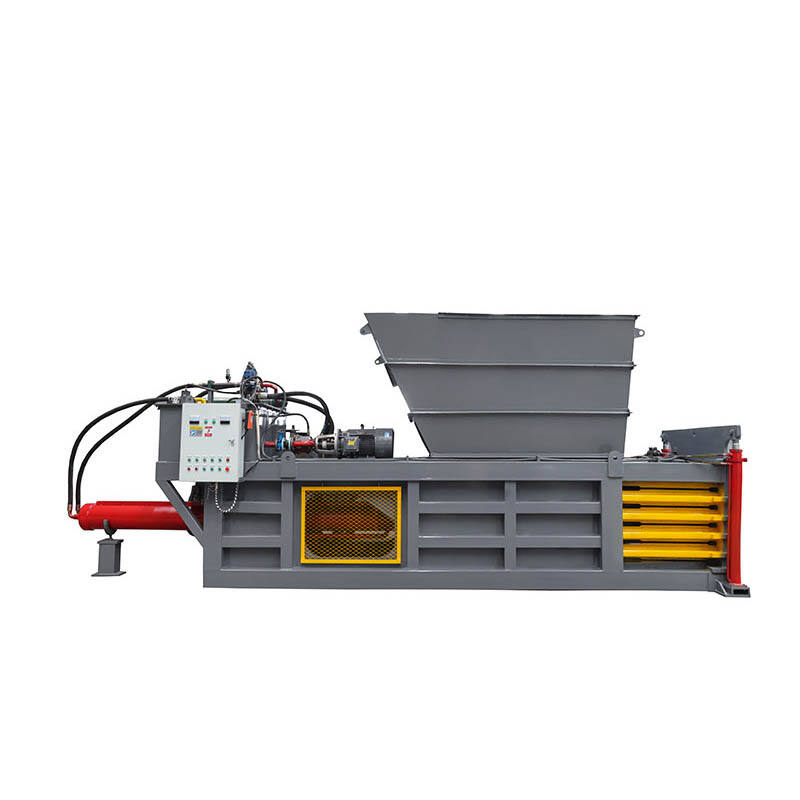

Automatic used clothes tire pet plastic bottle baler cotton waste packing machine

New horizontal cardboard compactor baler foam used automatic paper hydraulic cardboard waste pet baling press machine is the mechanical and electrical integration, the very high degree of automation of the packing machine, mainly by the mechanical system, control system, feeding system and power System and so on. The whole packing process is composed of pressure package, backhaul, suitcase, turn box, out of bag and package.

- Parameters

- Features

- Application

- Service

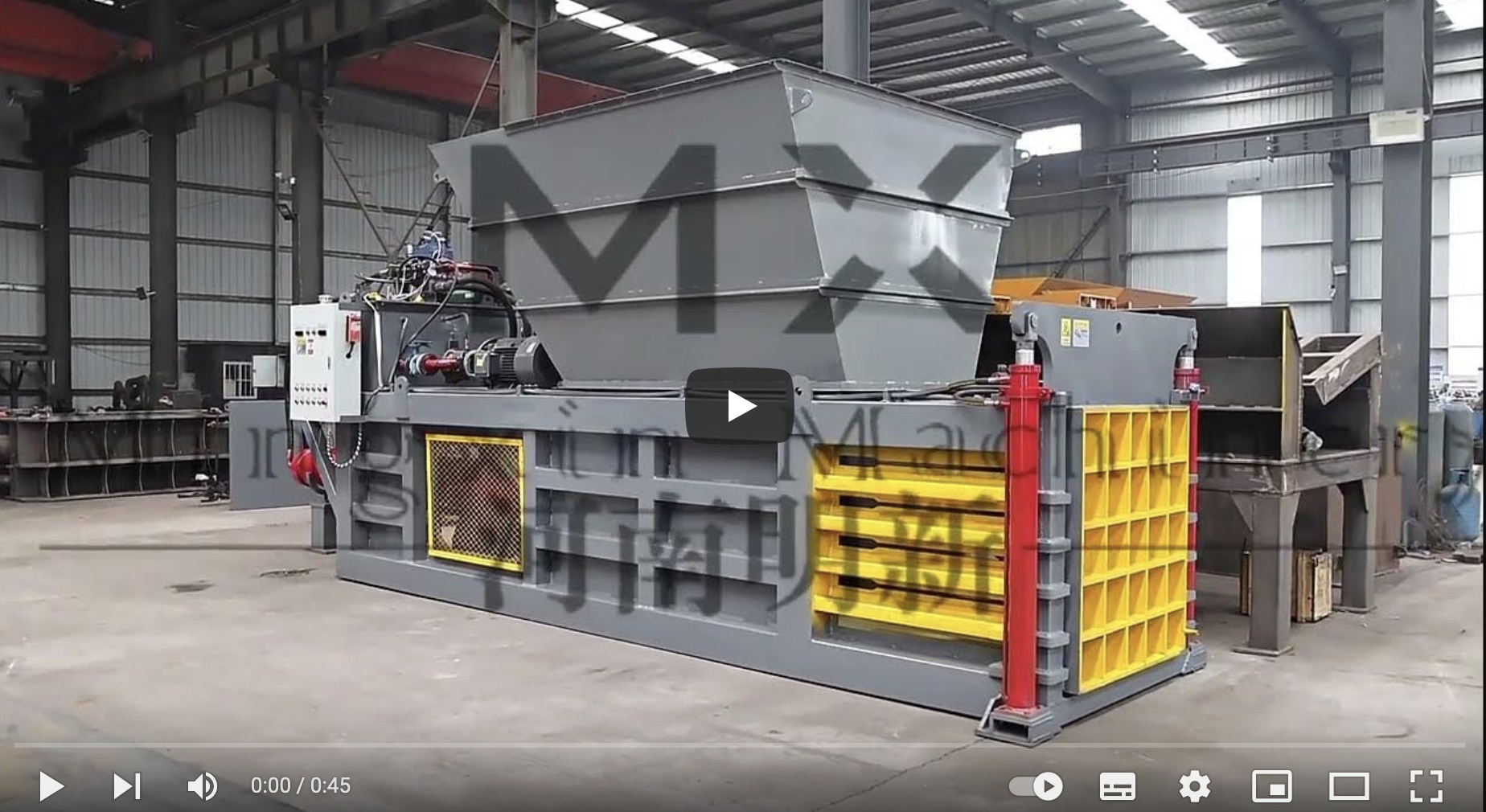

- Video

- Inquiry

- Related Products

Parameters

| Model | 80 | 120 | 160 | 180 |

| Power(kw) | 18+4 | 22+11 | 22+15 | 30+18.5 |

| Oil pump | 63 | 63+40 | 63+63 | 100+63 |

| Cylinder(t) | 100-130 | 150-180 | 200-300 | 280-300 |

| Dimensions(m) | 5.6*1.5*1.5 | 6.5*1.5*2.5 | 8.5*1.6*3.65 | 9*1.6*4.2 |

| Baling size(mm) | 1300*800*900 | 1500*900*1100 | 1500*1100*1200 | 1500*1100*1300 |

| Mouth size(mm) | 1400*800 | 1500*900 | 1600*1100 | 1800*1100 |

| Bale weight(kg) | 500 | 1000 | 1300 | 1500 |

| Capacity(bale/h) | 4-7 | 5-10 | 5-10 | 5-10 |

| Bale line | 5 | 5 | 5 | 5 |

| Nominal thrust (kn) | 800 | 1200 | 1600 | 1800 |

| System pressure (mpa) | 25-28 | 25-28 | 28.5 | 28.5 |

| Operation | Automatic | |||

Features

1. It is closed type hydraulic baler with lifting open-end door, no need to shift balers timely after package, it can push bags continuously.

2. It has high strength output door, hydraulic automatic open-end door, convenient operation and safety.

3. The horizontal hydraulic baler is operated by PLC with high efficiency and reduce labor.

4. Make the raw material to bales will reduce volume, increase density, it will be easy to transport and store.

Application

The hydraulic waste paper baler machine is widely used in baling straw, waste paper, carton, plastic bottle, etc. And mainly used for baling heavy and light impurities in paper mill stock preparation line.

Service

Pre-Sales:

Act as a good adviser and assistant of clients, enable them to get rich and competitive from the returns of their investment.

1. Select suitable equipment model.

2. Design and manufacture products according to clients special requirements.

3. Train technical personnel for clients.

4. Professional suggestion for customer.

Service During The Sales:

Respect clients, devote ourselves to improving the total value of clients.

1. Take photos ( including raw material, semi-products, final products and loading products ).

2. Pre-check and accept products ahead of delivery.

3. Prepare all clearance documents, so that the customer clearance smoothly.

After-sales service:

Provide considerate service to minimize clients worries.

1. Provide civil engineering drawings of the equipment.

2. Free training ( including installation, maintaince ) to every customer.

3. Install and debug the equipment, ensure the dryer running smoothly.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

VI

VI

TH

TH

TR

TR

LA

LA

TG

TG

UZ

UZ